The University of Brussels’ (ULB) Microgravity Research Centre (MRC) collaborated with PrintPlace on a groundbreaking project involving 3D design and 3D printing of a custom condensor. This intricately crafted component served as the linchpin of a research setup aimed at advancing heat transfer processes in microgravity environments. After rigorous testing, the component was chosen for inclusion in the European Space Agency’s (ESA) 73rd Parabolic Flight Campaign.

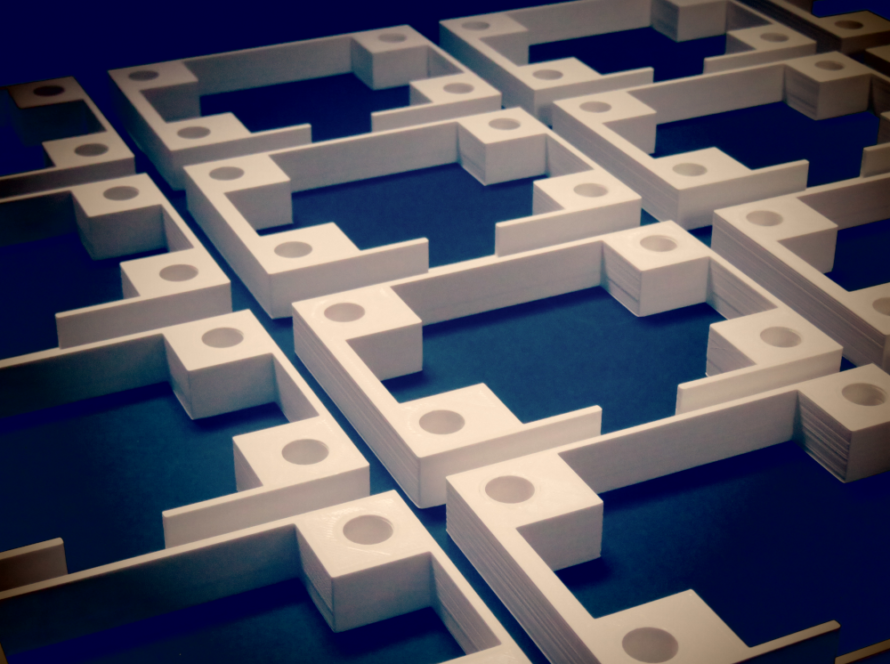

The MRC devised a sophisticated research setup focusing on evaporation-condensation processes, crucial for microgravity conditions where conventional methods fail. To address this challenge, a custom condensor was envisioned and printed. Collaborating closely, PrintPlace and MRC embarked on a comprehensive testing campaign, exploring various lattice designs, printing technologies, and materials.

After meticulous refinement and testing, a candidate component emerged, meeting stringent criteria for dimensional accuracy, thermal resistance, and chemical compatibility. This selected component endured rigorous tests, earning its place aboard the ESA’s 73rd Parabolic Flight Campaign in November 2020.

This collaboration underscores PrintPlace’s commitment to pushing the boundaries of 3D printing technology in groundbreaking scientific research.